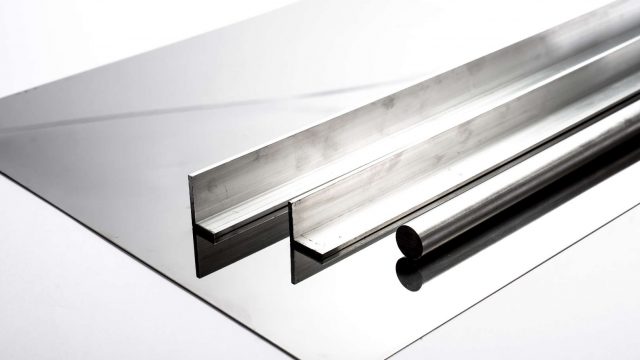

Stainless Steel Grades

We supply a range of grades for stainless steel and aluminium products, here’s a breakdown of all of the grades we offer.

Stainless Steel 304

Also known as 1.4301, this is the most commonly used austenitic stainless steel grade mainly due to its high corrosion resistance and its versatility.

It has excellent fabrication, machinability, weldability and folding qualities and can be extensively deep drawn too.

Typical Uses

- Sinks, splashbacks and general kitchenware

- Architectural panelling

- Pharmaceutical equipment

- Food factory equipment

- Signage

Grade 304 used to be known as 18/8 because it’s composed of 18% chromium and 8% nickel.

Grade 304L is a low carbon version of 304 and is used to improve the weldability of heavy gauge components. Some stainless steel plates and pipes have the properties of both 304 and 304L and are dual certified.

Our stainless steel meets the specification EN 10088-2:2005.

Some of our products are covered by ASTM, EN or other standards, which may contain a variety of specifications.

Stainless Steel 430

Grade 430 is a non-hardenable high chromium stainless steel sometimes known as grade 1.4016. It has good corrosion resistance, formability and ductility and provides a high quality finish. It is ferritic, meaning it is magnetic with a low carbon content.

Typical Uses

- Budget kitchenware

- Decorative trims

- White goods

- Flue linings

It is also lends itself well to chemical applications because it is highly resistant to nitric acid.

Our material are classed as EN 10088-2:2005. We also sell products covered by other standards such as ASTM, EN which may not have consistent specifications.

Aluminium Grades

Grade 1050A H14 aluminium sheets

Our aluminium sheets are supplied in grade 1050A H14 which is a medium strength alloy.

It is the purest alloy because it is made from 99% aluminium and is 100% recyclable.

It has excellent corrosion resistance, ductility and workability as well as high thermal and electrical conductivity.

Typical Uses

- Architectural flashings

- Signage

- Lamp reflectors

- A wide range of applications including electrical and chemical applications.

Because it has excellent corrosion resistance it is a popular choice for fabricating pressurised vessels and chemical tanks.

It is weldable as long as certain guidelines are followed because it has a narrow melting range. It is generally regarded as non-heat treatable and has low mechanical properties. Cold working can be used to slightly increase its strength.

6000 series aluminium long products

Our aluminium long products are supplied in the 6000 grade series, mainly as 6082T6 or 6063T6.

This is a medium strength alloy series with a high corrosion resistance. It is widely used for structural components.

Typical Uses

- Glazing sections

- Architectural applications

- Shop fittings

- Transport applications

6000 series aluminium contains manganese and silicon which means it can be heat treated to improve its strength. It is not as strong as series 2000 or 7000 series alloys but is one of the most versatile and heat treatable aluminiums.